which of the following is a type of machine safeguarding osha 10

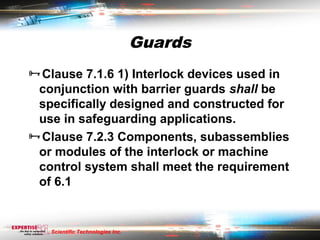

Types of Machine Safeguards Safeguarding machinery. Prevent contact keeping the workers hands arms or any other part safe from the moving part.

Safety Design For Machinery Safety Pilz Int

Which of the following is an example of a safeguarding device.

. The most common types of machine guards are. Types of Safeguarding Devices 13. The safeguarding system must have the following features.

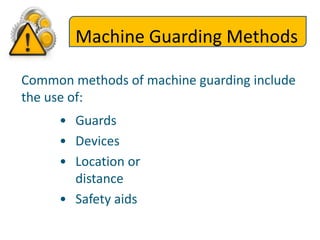

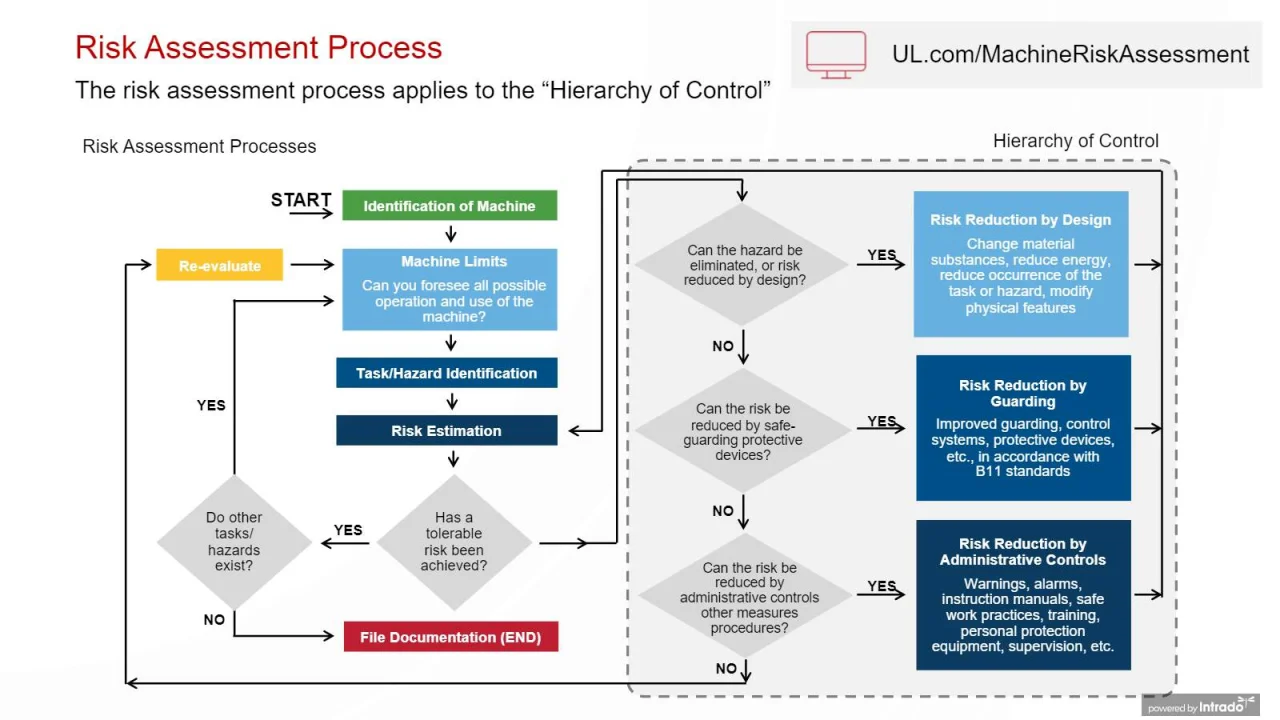

29 CFR 1910212 a 1 states that one or more methods of machine guarding must be used to protect operators and other employees from hazards including those created by point of operation in-running nip. Primary methods Guards Devices. Essential Updates To Machine Safety Standards Ul One basic form of machine guarding is called guarding by location According to OSHA this involves positioning or designing a machine so that the hazardous parts are away from areas where employees work or walk or alternatively installing enclosure walls or fences that restrict access to machines.

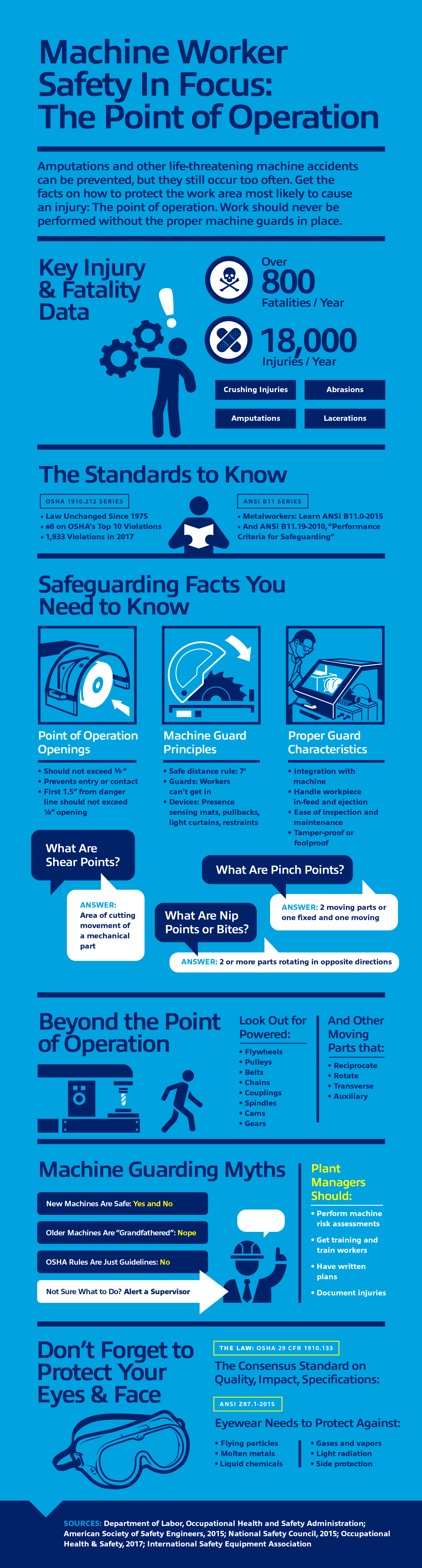

Any machine part function or process which may cause injury must be machine guarded. Must prevent workers from lubricating a machine without removing the safeguard Which of the following should employers prevent in order to ensure the safety and health of workers in regards to machine guarding. Machine safeguarding helps protect workers from preventable injuries in all three areas.

The Types of Machine Safeguarding. Any machine with moving parts needs specialized safeguards to minimize the chance of injuries. Moving parts covers a variety of components from pulleys to gears and beyond.

Avoids creating additional hazards. Moving parts in workplace machinery presents an immense danger to employees. Prevents employee contact with the hazard area during machine operation.

All machines consist of three fundamental areas. Machine guarding typically applies to the point of operation that is the location on or near the. For these reasons OSHA requires that certain pieces of equipment have specific protection mechanisms in place.

Machine Guarding Introduction. When the operation of a machine or. The following are all machine safeguarding requirements except.

Safeguards are essential for protecting workers from these preventable injuries. Criteria for Machine Safeguarding. Hosted by Chief Safety Officer Jill James you can listen to the webcast on demand.

Any machine part function or process that may cause injury must be safeguarded. Machine Guarding OSHA 10-Hour Outreach Training General Industry. Both types of safeguards need to be properly designed constructed installed used and maintained in good operating condition to ensure employee protection.

Guards and some types of safeguarding devices. A well-designed safeguarding system makes sure that the moving part is unreachable. There seem to be as many hazards created by moving machine parts as there are types of machines.

Machine guards are essential for protecting workers from needless and preventable injuries. Posted on 06162021 at 0338 pm Viewed 612 times. The following is an excerpt from Tackle OSHAs Top 10.

The following are all machine safeguarding requirements except. OSHA has set out a few general requirements that a safeguard must meet in order to ensure maximum protection. Examples of machine guarding include barriers light curtains and two-hand trips.

This is whats known as machine guarding. Despite all machines having the same basic components their safeguarding needs widely differ due to varying physical characteristics and operator involvement. Due to this fact OSHA Occupational Safety Health Administration has established a set of standards around machine guarding.

The point of operation the power transmission device and the operating controls. Likewise what are the 2 types of primary safeguarding methods. There are many ways to design and use machine safeguarding.

The type of operation size or shape of stock method of handling physical layout of the work area type of material and production requirements or limitations will help to determine the appropriate machine safeguarding method for the individual machine. So with regard to machine guarding the video above that youre seeing is actually from a supervisor safety tip video that we have hosted on our websit in our toolbox area where you can look for. Primary Safeguarding Methods Two primary methods are used to safeguard machines.

A good rule to remember is. Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands amputations burns or blindness.

Kpa Osha Machine Guard Requirement Compliance Checklist

Basics Of Machine Guarding Hazards And Solutions March

Essential Updates To Machine Safety Standards Ul

10 Safety Tips For Osha Standards Industrial Safety Gwg Personal Protective Equipment Ppe Industrial Safety Health And Safety Poster Workplace Safety Tips

Basics Of Machine Guarding Hazards And Solutions March

Moving Machine Parts Create Workplace Hazards And Potential Machinery Related Injuries Making Machine Guards Vitally Im Making Machine Machine Parts Workplace

Basics Of Machine Guarding Hazards And Solutions March

Machine Guarding Named To Osha S Top Ten Violations List For 2021 The National Provisioner

Basics Of Machine Guarding Hazards And Solutions March

2021 Top 10 Osha Violations Machine Guarding 2022 01 25 Ishn

Machine Guarding Safety Instructions Youtube

Machine Guard Infographic The Point Of Operation Better Mro